2. The Instructions on MD-2 Operations

A few important notes:

0. ALL sample/crystals manipulation should be done by ONE person ONLY. Under ANY circumstances, two people should NOT operate the MD2 at the same time ( like, one person is mounting the crystal, another one tries to center the crystal by clicking on the computer)

- Before any sample manipulation on MD2 – make sure all covers are closed as on Figure 7 below and the detector is moved back to 1000mm; Do NOT attempt to do anything if the capillary and the beamstop are in data collection mode or MD2 is in SAMPLE CENTERING mode. Please double check also that the robot gripper is not extending towards MD2.

- At any time two programs should be running on the MD2 operation computer, namely MD2_comwrapper and Micro-Diffractometer. Any deviation from standard operating procedures may result in termination of md2_comwrapper software. Should md2_comwrapper fails, you should wait ONE minute for md2_comwrapper auto-restart, if not -- manually restart it by double clicking the md2_comwrapper_server icon on the desktop of the MD2 operation computer.

- You are not allowed to adjust and move the cryostream nose back and forth. It is properly centered and fixed in a defined position and interlocked to the MD2 support table. Any movement of the cryo-head will result in a loud alarm and will damage your crystals.

- Currently MD2 is equipped with 3 different size apertures: 10, 30 and 70 microns. Check next paragraph - how to change the aperture size. ONLY your support personnel are allowed to physically moun/unmount different apertures.

Figure 7. General view of MD2 inside ID-C station with cover closed

Mounting a sample

- Make sure that MD2 software is in the data collection mode, if not click on it and wait until MD2 status says Ready ( bottom menubar of MD2 window )

- Move the detector to 1000mm by using ADSC manual control on the ADSC computer, if not moved automatically when the shutter is closed.

- Click on SAMPLE TRANSFER button in the MD2 software.

- Go inside the hutch and wait for the capillary/beamstop/aperture assembly to move under the cover. (if after pressing SAMPLE TRANSFER, the covers are not closed, press Data Collection, wait 30 seconds and press again SAMPLE TRANSFER button)

- Gently mount your sample using cryo tongs, or use vial-mount with mini-kappa.

Centering a sample

- Click on Sample Centering button on the MD2 software and wait for the sample illuminator to pop up.

- Perform 3-click centering at zoom factor of 1

- Perform 3-click centering at zoom factor of 8 (or anything reasonable).

- You may use < and << or > and >> buttons on "Data Collection Axis" to manually rotate the PHI axis and double check the crystal alignment

- To manually center the crystal – use Alignment Horizontal Translation and Centring Vertical Translation tabs and the corresponding arrow buttons to center the sample.

Auto-aligning of MD2 table

- It may not be necessary to do this for every sample. Do this at least once in an hour. It may be needed do it more often if the incoming beam is unstable, or for very small crystals.

- Interlock the station C and open the station C shutter ; wait until the SYSTEM READY.

- On MD2 computer make sure you are in a Beam Location mode.

- On the auxilliary computer press AUTO ALIGN button on EXECUTOR window: three more windows will popup – see the Figure 8 below. Please be patient –let the system to find the beam!!! It takes 1-2 minutes to properly position the beam.

- Wait for the system to finish finding the beam and moving the MD2 table. Once it’s done, the system will announce "Beam alignment is complete"; three popup windows will close. The system will continue the beam tuning for a while. In a minute the status of the beamline will be SYSTEM READY

Figure 8. User workspace on auxiliary computer during autoalignment of the beam.

Note 1 : The above procedure is done automatically after any energy change more than 500eV, or before EXAFS scan;

Note 2: Do NOT open the hutch door or close the main shutter, if the system is doing an autoalignment. The MD2 table may be moved to the limit positions and severe mechanical collisions may occurs. Also the beam may be lost because the system will try to optimize zero level flux and will move the mirrors to the wrong positions: Check the troubleshooting section how to recover the lost flux

Note 3: Please always watch the status of the control system: don’t do anything until the system tells you SYSTEM READY.

Note 4. The alignment of the MD2 table may be done manually, see chapter below

Note 5. The AutoAlignment feature can be disabled by pressing "OPTIONS" and selecting "Defeat AutoAlign" on Auxialiry compute.

It is convenient during multiple EXAFS scans –

Don't forget to enable it back, when necessary.

Manual Locating of the beam

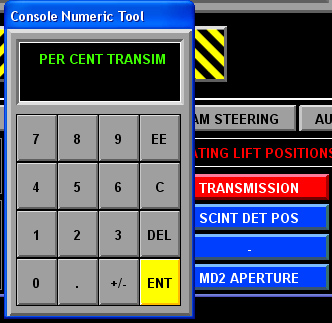

- On the auxilliary computer press TRANSMISSION and type 1.5 in the new popup window ( that will setup 1.5% transmission) .

- On MD2 computer make sure you are in a Beam Location mode.

- Once scincillator BGO crystal is in place for beam visualization, set a zoom factor of 7.

- On MD2 control computer click on OUT for both aperture and capillary beam stop.

- Click on open/close shutter – when the shutter is open, you should see the hot spot of the beam aligned to the red circle (Figure 10a). If it’s too bright, decrease the flux/transmission.

- If it is not aligned, click on the up/down (lift) or left/right (transverse) arrows on the MD2 table control (Figure 5) on the auxilliary computer to move the hot-spot to align with the red circle to your satisfaction.

- On MD2 control software click on In button for capillary/beam stop assembly and wait for the assembly to move in place.

- On MD2 control software, use tune function of capillary/beam stop assembly to align it to the beam hot spot, to your satisfaction See Figure 10b above.

- On MD2 control software, click on In button for the aperture and wait for the aperture to move in place.

- On MD2 control software, use tune function of the aperture to align it to the beam hot spot, to your satisfaction. See Figure 10c above

- On MD2 control software, click on OPEN/Close shutter.

- Reset the transmission to needed for data collection values on the auxilliary computer.

Figure 9. Chosing a proper transmission in percents; type the number and press ENT.

Figure 10. Different stages of beam alignment on MD2

Changing the aperture size

- Interlock the station C and open the station C shutter

- On MD2 computer make sure you are in a Beam Location mode.

- Go to the AUXILLIARY computer and click MD2 APPERTURE button

- Select the desired aperture size.

- If it is not changed automatically, you may need to change size of the red circle/ellipse on MD2 window (use “change size” dialog in the lower right cornet of MD2 window)

The following procedures are not always necessary for

50x70 micron beam , and should be done only if the incoming beam is

not perfectly centered on the red circle/ellipse. See Figure 10c

above

- On the AUXILLIARY computer select ~1.5% transmission. Switch back to MD2 computer

- Make sure that MD2 software is in the BEAM LOCATION mode, if not click on it and wait until MD2 status says READY ( bottom menubar of MD2 window ) ; the scincillator BGO crystal should be in place for beam visualization

- Open the fast shutter and watch the beam coming. If it’s too bright, decrease the flux.

- On MD2 control software, use tune function of the aperture to align it to the beam hot spot, to your satisfaction. See Figure 10c above

- Click OK to save new aperture position

Data Collection

- Make sure that station C is interlocked and station C shutter is open and there is stored beam in the ring (check the panel, showing two green lights, above the ADSC computer) – Figure 1.

- On MD2 control software, press Data Collection - wait 10 seconds until the MD2 system is in READY state ( bottom menubar of MD2 window )

- If you are not familiar with ADSC software, refer to the details for data collection in the next section on "How to collect data"

- Using the ADSC software, collect first snapshot and analyze the results: you may need to adjust the attenuator and the exposure time. Note: start with a low flux beam to prevent unnecessary radiation damage.

- Setup the appropriate data collection protocol based on the estimated strategy and collect data.

Changing to a new sample

- Make sure that MD2 software is in the data collection mode, if not click on it and wait until MD2 status says Ready.

- Move the detector to 1000mm by using ADSC manual control on the ADSC computer.

- Click on Sample Transfer button on the MD2 software.

- Go inside the hutch and wait for the capillary/beamstop/aperture assembly to move under the cover. (if after pressing Sample Transfer the covers are not closed, press Data Collection, wait 30 seconds and press again Sample Transfer button)

- Unmount the sample gently from the goniostat either using hands or using cryo tongs.

Note 2: If you decide to stop data collection in the middle of the run, the GUI of MD2 windows may remain locked until you press "UNLOCK" button (right lower side of the MD2 window)

Washing a sample using LN2

Note: Do not pour LN2 on your crystal when MD2 covers are in open

position. Do not pour LN2 on your sample without gently covering the

MD2 with the weight boat provided by your support personnel: do NOT use

any other covers.

LN2 is very dangerous for internal

parts of MD2

- Click on Sample Transfer button on the MD2 software.

- Go inside the hutch and wait for the capillary/beamstop/aperture assembly to move under the cover. (if after pressing Sample Transfer the covers are not closed, press Data Collection, wait 30 seconds and press again Sample Transfer button).

- Place the provided protective weight boat to cover the MD2 and use the provided "baby formula" spoon to pour LN2 on your sample. Rotate the crystal and repeat washing if necessary (you may manually rotate the crystal by holding the base of the sample )

- Remove the protective cover from MD2.

Taking pictures of your crystals

If you like the view of your mounted crystal and want to save it, you may do so: Adjust the viewing angle and the camera zoom (in a "Sample Centering"mode. Click on the "CAMERA" icon in the "Tools" tab on the Microdiffractometer software menu (just below the crystal view area), select "File Prefix" and the format (either PNG or JPEG); don’t change the destination directory. Click "Save" and "Close". The image you see in the graphics window will be saved and later may be copied to your storage (see data backup section).

Using of mini-kappa mount

The microdiffractometer on 24ID-C may be equipped

with mini-kappa

goniometer , which is designed for orienting crystals on the data

collection axis of a host goniometer (OMEGA).

Currently, the use of mini-kappa goniometer is permitted ONLY under direct supervision of the beamline scientist.

The use of mini-kappa mount is described in more details in Chapter 10.

3. Robot operations

The robot is under active development now. Robot operation instructions are currently available by pressing HELP button in the robot script window or by pointing your browser to: http://lilith.nec.aps.anl.gov/~perry/index.html - general information about NE-CAT robot or proceed to the Next Chapter "Robot Operations"