2. Robot operations

Inside

the

hutch

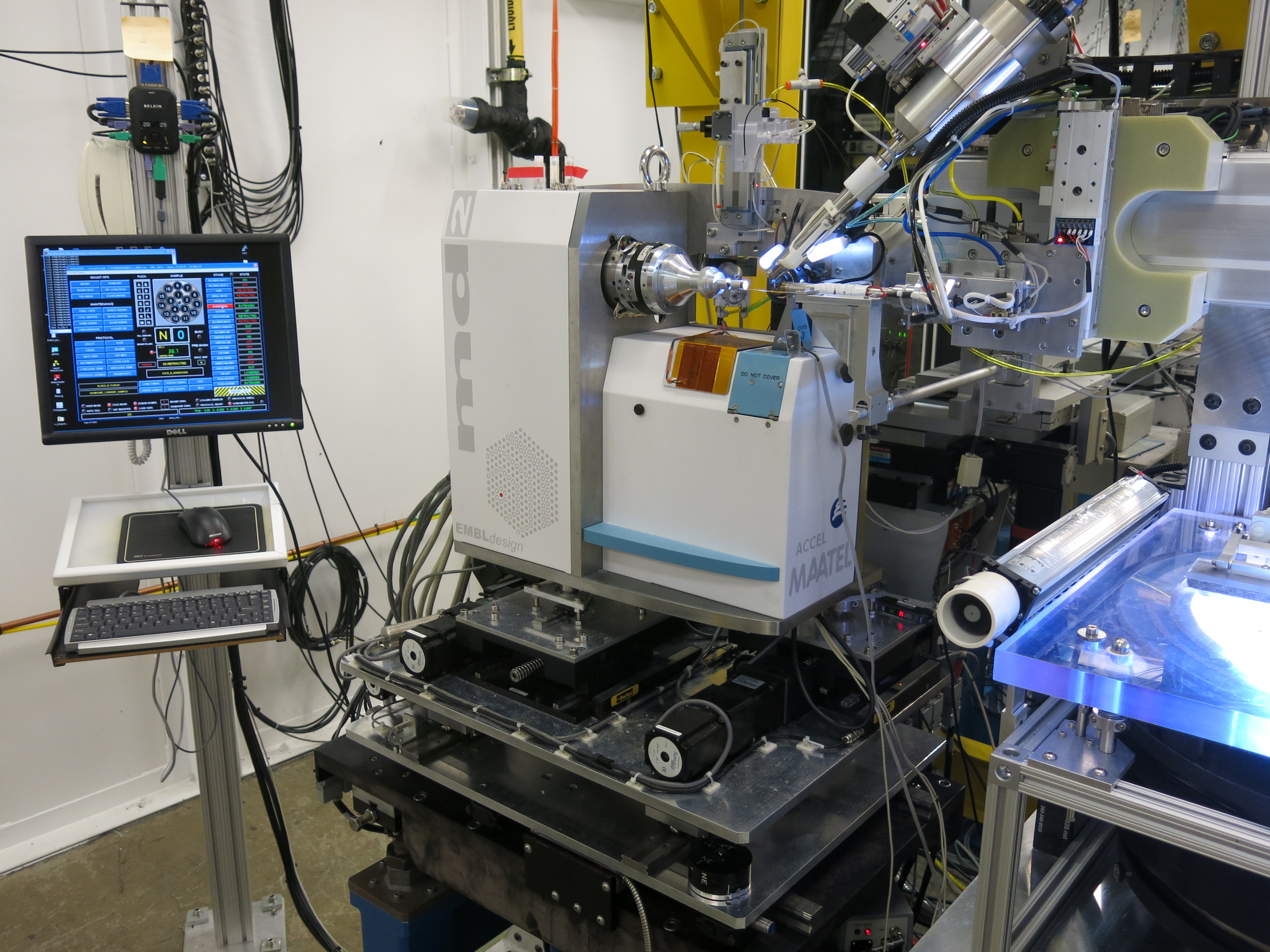

Figure 3. General view of robot control computer (left), MD2 and robot dewar (at right) inside C-hutch.

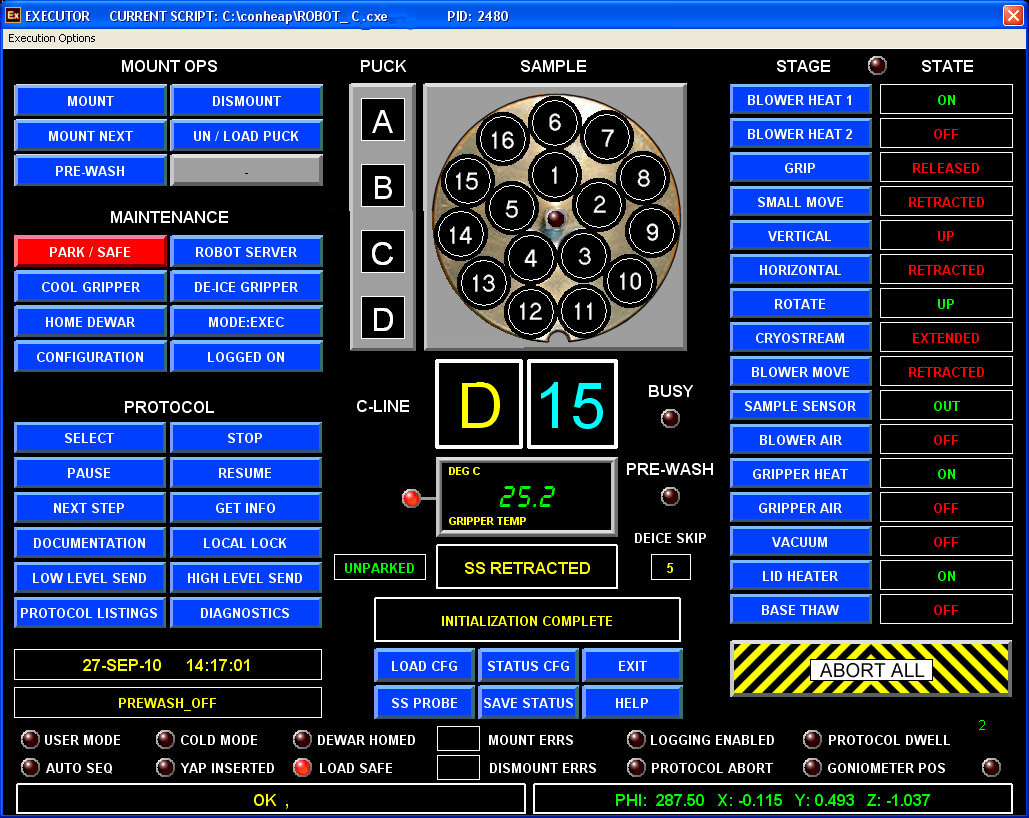

Figure

3B. The main working window for all robotic applications INSIDE the

hutch

Unload/Load Pucks

1. Remove any mounted crystals on

the goniometer, either manually or pressing DISMOUNT button.

2. Click on PARK/SAFE, select "park

gripper" and script will ask you to confirm. Click YES. The robot

script will then perform several sanity checks:

* If MD2 is

not closed, then the capillary/beamstop will be retracted under the

cover.

* Sample on

the Goniomter - The sample sensor will detect if there is a pin on the

goniometer. If a sample is present, the robot script will ask you to

remove the sample or allow the robot to place the sample back in the

dewar. If you choose to manually remove, the sample sensor will retract

to allow you to reach the pin. The sample sensor may be manually moved–

click on “SS PROBE”

Once the spindle is unoccupied, and

all covers are closed, the robot script will park the gripper.

You should wait and NOT touch

anything before the gripper stops in Park Position (facing goniometer).

3. Click UN/LOAD PUCK.

Next a new popup window will appear – select a puck position (A to N)

or CANCEL the operation.

After puck selection, the dewar will

rotate that position directly under the opening and allow for placement

of a puck. There are four positions in the dewar: A, B, C, and D, which

accessible from the inner openning; positions E to N are accessible

from outer openning. Keep

track of which puck goes in which position. After the gripper has been

parked, you can access the dewar.

4. Turn off the lid fan for

better

viewing. Before pucks can

be loaded, the lid must be removed.

5.

Remove the puck from the shipping

cane. Turn over the puck so

that the thick part of the puck is face up. Attach the puck pusher to

the puck. Orient the puck so that the notch is facing the center of

the dewar. Load your puck into the dewar by lowering into the liquid

nitrogen and feeling for engagement of the notch with the pin. It is

recommended to slightly tilt the pusher toward the center of the

dewar. When the puck is engaged, then it will not move in the dewar

and the puck pusher will be perpendicular to the opening of the

dewar. The puck will also be seated inside all three pins. Once the

puck is engaged, push down with the plunger (of the puck pusher) to

separate the two pieces of the puck. Then lift straight up in order

to avoid disturbing the pins. Visually check the alighnment of ALL

pins, use long (and cooled) forceps to place properly tipped over

pins.

7. After loading your puck into the dewar, select

the next position by first clicking UN/LOAD

PUCK, confirm, and then choosing the next position. Due to

the sanity checks, this step is slow. Repeat steps 3-6, until up to

fourteen pucks are in the dewar.

8. Once all your pucks are

loaded, replace the lid on the dewar (make sure the pin on the dewar

is engaged in the lid) and turn the fan back on.

9. You

must cool the gripper before samples can be mounted. Click COOL

GRIPPER. The gripper should enter the dewar and begin

cooling. Once the proper temperature has been achieved, you will be

able to select a puck (click A to N) and a sample (click a

number in the puck picture). Now, sample mounting can proceed. It is

recommended to mount the first crystal inside the hutch, to check

proper alignment of the robot. Once PuckID and Sample# changed color

to yellow/cyan – press “MOUNT”

button and watch the robot mounting the first crystal.

Now all robot operation should be done OUTSIDE the hutch, using the robot script running on auxiliary computer.

Outside the Hutch

All robot operation can done OUTSIDE

the hutch, using the

XTAL CENTERING tab

To mount/unmount samples:

1. To mount your first sample click

the Puck ID (A to N), then click the Sample ID (#1-16). The

Puck ID and Sample ID colors will change to red as the robot moves to

the sample location. When the dewar move is complete, the Puck ID

color will change to yellow and the Sample ID will change to cyan.

Make sure that the BUSY light is green (not bright red),

ROBOT READY and the status is

DISMOUNTED

2. Then click MOUNT under Mount

Ops. The robot will start

mount the selected

crystal;

Be

Patient – it takes ~50 seconds to finish!

When the sample

has been mounted, the voice will state, "Ready to Align Sample."

At this time, you may align/center your crystal. The robot is still

busy doing first de-icing of the gripper and second cooling it.

Please do not click anything in the robot window at this time

3.

Mount Next Sample. With a sample mounted on the goniometer, you have

two choices.

* If you wish to

go to the

very next sample in the puck, then click MOUNT

NEXT. The robot will dismount

the sample and mount the

next sequential sample. When it is complete, the voice will state,

"Ready to Align Sample." Be patient – it takes ~115

seconds for this step.

* If you wish to

go to new sample in the same puck, then click the Puck ID and then

select Sample ID of the desired sample. The puck IDs will change to

red, then back to yellow and Sample ID will change to cyan when your

selection has been accepted. The robot will dismount the current

sample and automatically mount the chosen sample. When the mount is

complete, the voice will state, "Ready to Align Sample." Be

patient – it takes ~125 seconds for this step.

* If you wish to mount a crystal from a different puck, it is

recommended to first click DISMOUNT before selecting your new sample.

The robot will return the currently mounted sample to the puck. Once

the crystal is dismounted, the BUSY light is green (not bright red),

ROBOT READY, click the Puck ID

and then select Sample ID of the desired sample. The puck IDs will

change to red, then back to yellow and Sample ID will change to cyan,

then your selection has been accepted. The robot will move to the new

location and automatically mount the chosen sample. Be Patient – it

takes ~70 seconds to finish! The voice will then state, "Ready

to Align Sample."

* The above

behavior may be changed by checking “Automount Disabled”: in the

Maintenance submenu – the crystal will

be NOT automatically mounted after new selection. You need to click

MOUNT to mount the selected

crystal.

4. Dismount -This command returns

the

currently mounted sample to the puck. (duration ~80 sec)

5. OPTIONS button will give you the menu with different washing scenarios. The most commonly used are:

POST_WASH to wash the crystal after mounting : it instruct the robot to move the crystal back to the dewar, move it back and forth to remove any ice on the loop surface and mount it back.

WASHING MACHINE – The whole dewar is strongly agitated several times to remove ice from many crystals at once; it is recommended to perform this operation after loading your pucks

ENABLE PRE_WASH – Before mounting every new crystal, the gripper will be agitating up and down with every crystal before mounting.

6. If a long time has passed between

sample mounts (such as the

duration of a long data collection), De-Ice

Gripper and then Cool Gripper

prior to dis-mounting. Ice builds up on the gripper during long

intervals and will enter the storage dewar if not removed by

de-icing. Ice in the storage dewar is drawn to any crystals

present.

7. To move the gripper into a safe state for

maintenance (or after finishing the experoment) - click SAFE

GRIPPER.

Aborting

/

Restarting

Robot

Operations

1. If one of the stages is UNDEFINED or there is some form

of

mechanical emergency with the robot, you can stop the Robot by clicking

ABORT ALL (inside the hutch). If the ABORT ALL

button is used during

regular operation, it will cause the Robot to cease, the PROTOCOL ABORT

light will illuminate and further action will not be possible until the

abort has been cleared. Improper clearing of the abort can cause random

robot actions and sample loss. If a physical obstruction is the cause

of the UNDEFINED

state, the obstruction must first be removed prior to

clearing the state. The UNDEFINED state can be cleared by clicking the

stage motion (inside the hutch in the superuser mode ), so that the

state return to normal. To clear the abort,

you must exit the script and restart.

2. If you cannot exit from the Robot

script by pressing EXIT, you

can

abort the script by clicking on Execution Options under the title bar

and then selecting Abort Script.

3. To restart the Robot software

double click the EXEC_Intel icon on the desktop . Click on File

and choose “Prior .CXE Selection”, drag the mouse to the right to

select the script “C:\CONHEAP\ROBOT_C.CXE”. Click on “Execution

Option”

and choose “Execute Script”. Now you should see the new robot window

coming (Figure 3B). After initialization of

the script (be patient),

the robot is ready.

4. The Robot Server should be only

be restarted inside the hutch. If

the Robot Server has been restarted, the socket connections on the

outside beamline computer must be re-established. On the beamline

auxilliary computer, click the ROBOT

SERVER button under Maintenance tab

menu. You will be asked to confirm. Click YES.

General notes for robot trouble-free operations:

Note1:

The robot is

SLOW

– You can’t make it faster: every operation is a set of many

instructions and sanity checks, which should be completed before the

software can accept a new command. Please be patient, and wait every

instruction to be properly finished. Aborting, canceling or just

double-clicking may push the system in the delirious state with long

recovery time.

Note 2: Please

always watch the status of the robot system: When

the robot is ready for the new operation/command it will display

green ROBOT READY status.

Note 3. Double

check the video feed on the computer screen above for robot gripper

position (it should NOT be protruding into MD2) BEFORE “unlocking”

the MD2 computer.

Note 4: Please follow ALL

instructions from your support personnel. Any deviations or shortcuts

are dangerous and will lead to unpredictable results and/or physical

damage of the equipment.